1. Why Insulation Choice Directly Impacts Building Performance

Insulation is no longer just about meeting minimum thermal requirements. In modern construction, it directly affects energy consumption, indoor comfort, moisture control, air tightness, and long-term durability. As building envelopes become more complex—featuring curtain walls, prefabricated elements, and lightweight structures—the limitations of traditional insulation materials are increasingly exposed.

Polyurethane (PU) foam has gained wide adoption in global construction markets because it combines thermal insulation, air sealing, and mechanical stability in a single material. Compared with conventional insulation such as fiberglass, mineral wool, EPS, or XPS boards, PU foam offers measurable performance advantages, particularly in joints, cavities, and irregular interfaces.

As a professional manufacturer, Siway supplies polyurethane foam systems designed specifically for construction, window and door installation, prefabricated buildings, and industrial applications where performance consistency matters.

2. What Is PU Foam? Understanding the Science Behind Polyurethane Insulation

PU foam is formed through a controlled chemical reaction that creates a closed-cell structure filled with insulating gas. Once cured, the foam becomes dimensionally stable and permanently bonded to surrounding substrates.

Key material characteristics include:

-

--Very low thermal conductivity, delivering high insulation value with minimal thickness

-

--Strong adhesion to common construction substrates

-

--Expansion that fills gaps completely, eliminating voids

-

--Resistance to moisture penetration and air leakage

-

--Long-term stability under temperature cycling

Unlike loose-fill or board insulation, PU foam does not rely on mechanical fixing or perfect cutting accuracy to perform effectively.

3. Thermal Performance: Where PU Foam Has a Clear Advantage

Thermal efficiency is typically measured by thermal conductivity (λ-value). Lower values indicate better insulation performance.

In practical applications, PU foam consistently outperforms traditional materials:

-

--PU foam achieves high R-values even in thin sections

-

--Performance remains stable over time, without sagging or settling

-

--Thermal bridges around frames, anchors, and penetrations are effectively eliminated

By contrast, fiberglass and mineral wool lose effectiveness when compressed or exposed to moisture, while rigid boards depend heavily on flawless installation and joint sealing to maintain performance.

For window and door installations, where space is limited and geometry is irregular, PU foam delivers insulation results that traditional materials struggle to match.

4. Airtightness and Energy Loss Controlv

Heat loss through uncontrolled air leakage is one of the most significant contributors to energy inefficiency in buildings. Traditional insulation materials are not air barriers. Even when installed correctly, they require additional membranes, tapes, or sealants to control airflow.

PU foam inherently functions as both insulation and air seal. Once applied, it:

-

--Seals micro-gaps and irregular cavities

-

--Bonds continuously to surrounding substrates

-

--Prevents convective heat loss

-

--Reduces drafts and pressure-driven air leakage

This dual function is particularly valuable in energy-efficient buildings, modular construction, and retrofit projects where achieving airtightness is challenging.

5. Moisture Resistance and Long-Term Reliability

Moisture management is a critical factor in insulation performance and building durability. Water ingress can significantly reduce thermal efficiency and lead to mold growth or material degradation.

PU foam’s closed-cell structure limits water absorption and helps control vapor movement. This makes it well suited for:

-

--Window and door perimeters

-

--Basement and foundation interfaces

-

--Cold rooms and refrigerated facilities

-

--Humid or coastal environments

In contrast, fiberglass and mineral wool are highly sensitive to moisture, while board insulation systems rely on perfectly sealed joints to prevent water intrusion.

6. Structural Contribution and Mechanical Stability

While insulation is not typically considered a structural element, PU foam provides a meaningful reinforcement effect in many applications.

When cured, PU foam adds stiffness and load distribution around frames and cavities. This is particularly beneficial in:

-

--Window and door installation

-

--Lightweight steel framing systems

-

--Prefabricated wall panels

-

--Modular building connections

Traditional insulation materials do not contribute to structural stability and may even shift or compress over time, reducing effectiveness.

7. Installation Efficiency and On-Site Practicality

From a contractor’s perspective, installation speed and reliability are just as important as material performance.

PU foam offers clear on-site advantages:

-

--Single-step application

-

--No cutting or fitting required

-

--Rapid curing and early handling strength

-

--Consistent performance across irregular geometries

This reduces labor time, minimizes installation errors, and improves overall project efficiency—especially in high-volume or prefabricated construction environments.

8. Where PU Foam Clearly Outperforms Traditional Insulation

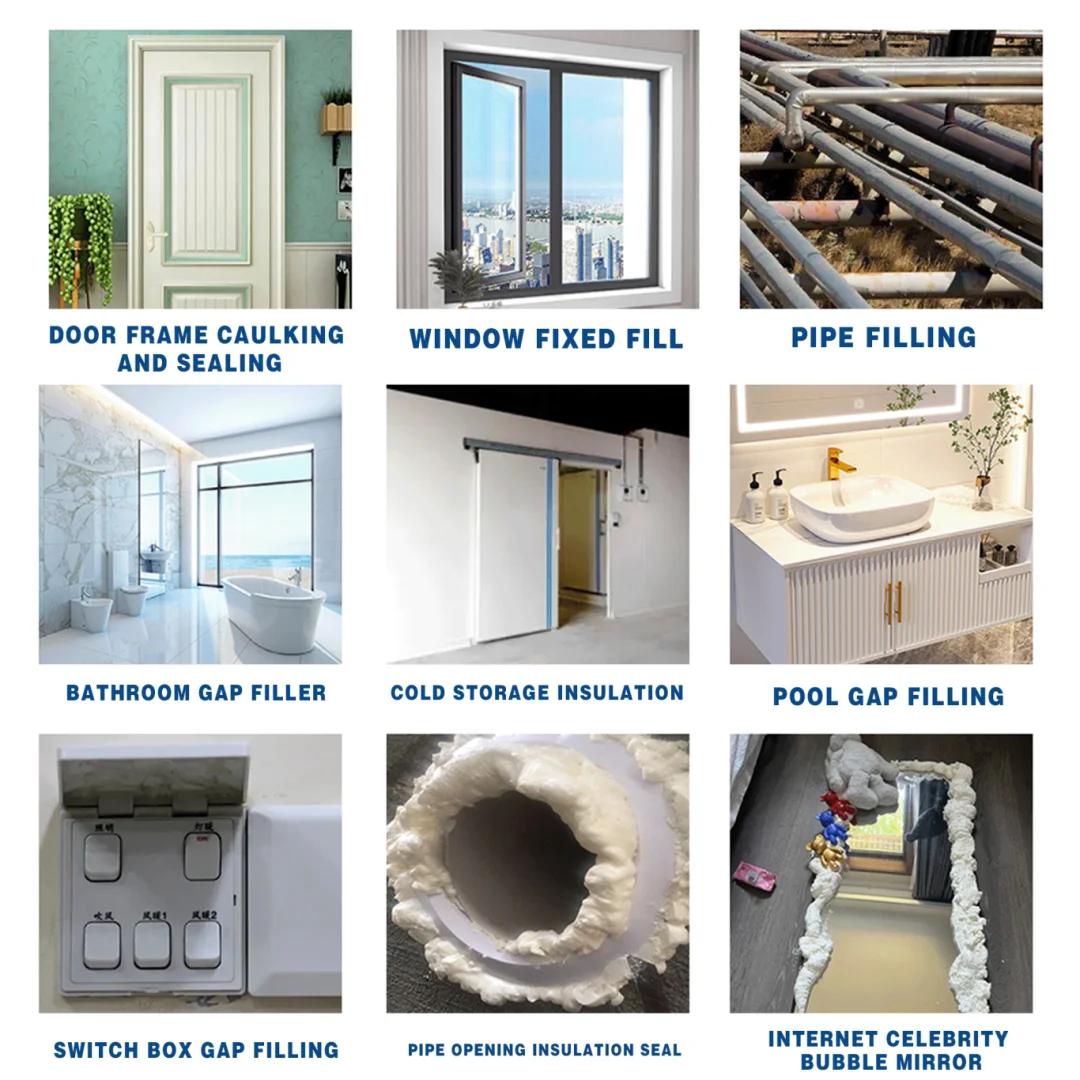

PU foam is particularly well suited for:

-

--Window and door installation

-

--Curtain wall perimeter sealing

-

--Prefabricated and modular buildings

-

--HVAC and service penetrations

-

--Cold storage and temperature-controlled facilities

In these applications, the combined requirements of insulation, air sealing, moisture resistance, and durability are difficult to meet using traditional materials alone.

9. Siway PU Foam Solutions for Professional Construction

Siway develops polyurethane foam products specifically for professional use, including:

-

--Low-expansion window and door installation foam

-

--High-yield gap filling foam

-

--All-season and winter-grade formulations

-

--Fire-rated PU foam for regulated applications

Each product is engineered for controlled expansion, stable curing, strong adhesion, and long-term performance across a wide range of climates and construction systems.

Siway PU foam is compatible with concrete, masonry, aluminum, steel, PVC, wood, and composite substrates, making it suitable for both residential and large-scale commercial projects.

10. A Practical Shift Toward Higher-Performance Insulation

PU foam is not simply an alternative to traditional insulation—it addresses many of the performance gaps that conventional materials cannot. By combining thermal efficiency, airtightness, moisture resistance, and mechanical stability, PU foam supports modern construction requirements more effectively and more reliably.

For contractors, designers, and developers focused on long-term building performance and energy efficiency, PU foam—especially professional-grade solutions from manufacturers like Siway—represents a practical and proven choice.

Learn more about Siway’s polyurethane foam systems:

Post time: Dec-18-2025