SV B1 Fireproof Self-expanding Polyurethane Foam

Product Description

FEATURES

1. Normal applicable temperature of tank : + 5 ℃~ + 35 ℃

2.Optimum operating temperature : + 18 ℃ ~ + 25 ℃

3.Temperature resistance range after curing : - 40 ℃ ~ + 90 ℃

4.Normal applicable humidity: ≥ 45 %

5.Good adhesion to most substrates ( excluding PTFE, PE, PP ), If used on metal parts, it should be coated on the metal surface

6.Excellent thermal and acoustic insulation

7.Excellent installation ability with doors and windows

8.Good control ability if using matching spray guns

9.Good void filling ability (self-expanding )

10.Quick curing: Tack free time is 10 min ; The foam can be cut , polished or painted for 60 minutes

11.Vibration resistance: Elastic and buffering

12.Safety: After the product is cured, there is no harm to the human body

COLOURS

SIWAY® B1 is available in white,red and other customized colours.

PACKAGING

Aerosol, 750 mL

Keep straight

TYPICAL PROPERTIES

Typical property values of SIWAY® B1-FR as supplied and cured are set forth in the tables below. Typical data below should not be used as specifications development. Assistance with specifications is available by contacting SIWAY at 0086-18016469848.

| TEST ITEM | UNIT |

TYPICAL VALUE |

TEST METHOD OR STANDARD |

| Density | kg/m3 | 18 |

FEICA TM1019 : 2014 -With no skin |

| Expanding times | times | 54 |

FEICA TM1003 : 2013 |

| Dimensional stability ( 23 ℃, 7 d ) | % | 5 |

FEICA TM1004 : 2013 |

| Tensile strength ( aluminum panel ) | kPa | 130 |

JC 936-2004 |

| Shear strength ( aluminum panel ) | kPa | 125 |

JC 936-2004 |

| Burning level | class | B1 |

JC 936-2004 |

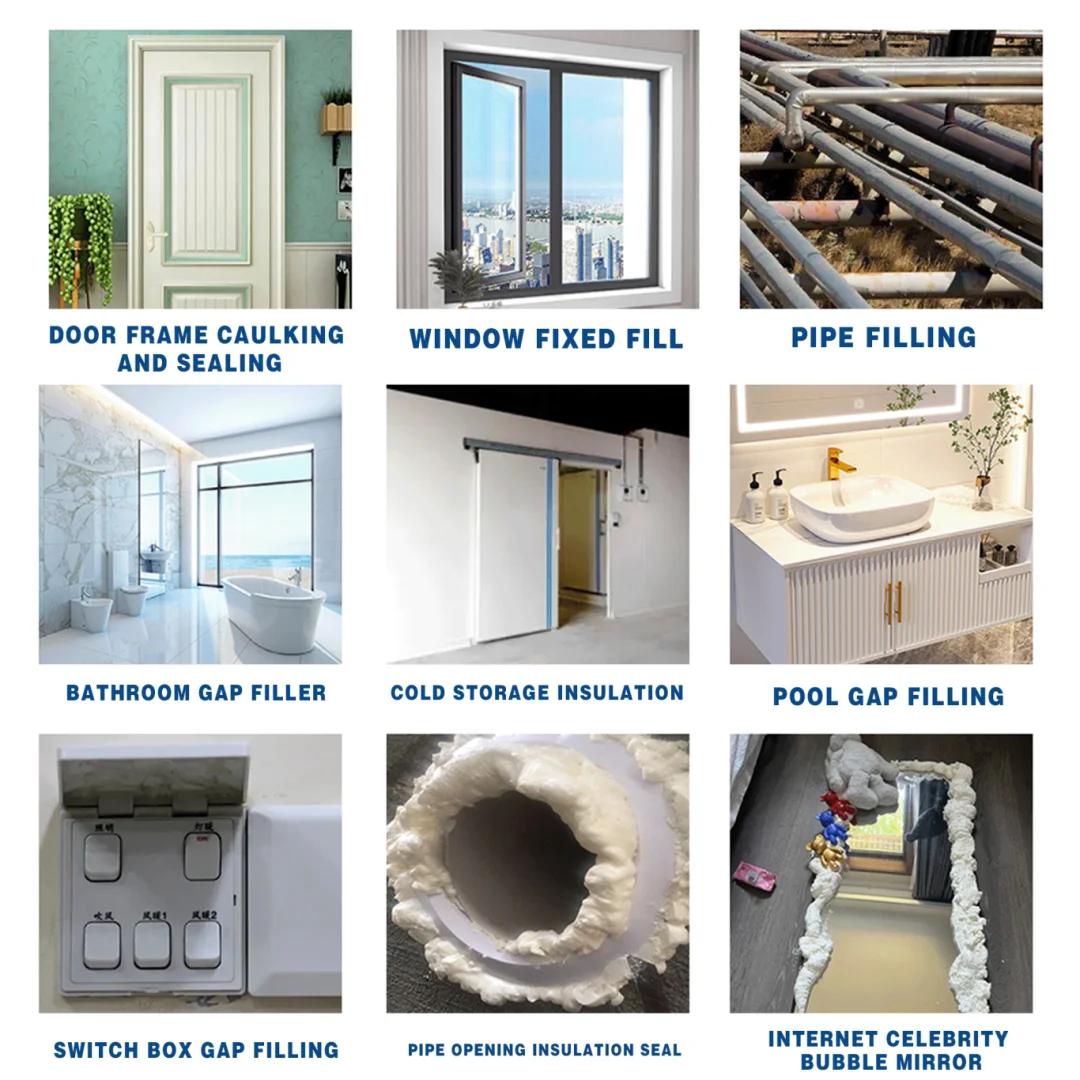

Applications

1.Installation and fixing of door cover and window frame

2. Filling of soundproof walls

3. Sealing and filling of wall pipes

4. Filling of voids such as walls and roofs

5. Filling of cabinet wall to moisture-proof

6. Insulation filling of refrigerators, sinks, bathtubs, etc.

Shelf-life and storage

12 months in dry and cool place at 18 ℃ ~ 22 ℃

Health and Safety Advice

The product should avoid direct sunlight, and the storage temperature should not exceed 50 ℃

Keep the cans out of reach of children

Do not approach open flames or contact with flammable and explosive materials; Do not pierce or burn even after use

Severe bumps and collisions are strictly prohibited during transportation, and it is forbidden to put in the cab.

Ventilation conditions when using, and no smoking

Reference product label

Notice

The construction surface should grease-free, oil-free and dust-free, and the construction surface should be fully moistened ( spray a little water )

SIWAY PU foam gun is recommended to improve construction quality

When spraying from bottom to top, pay attention to the expansion of foam

If you need to replace a new can, shake the new can for one minute, then unscrew the empty one, and clean the connection port of the spray gun with a special foam cleaner. Replace the new can as soon as possible to prevent the connection port of the spray gun from solidifying

After using it, please clean the spray gun thoroughly with cleaner immediately

When spraying in layers, spray water mist before spraying each layer

The cured PU foam is not resistant to UV-rays. Therefore, other coatings ( such as cement mortar ) or sealant should be used to protect the foam surface

Limited Guarantee

The indicators and data given in this information are based on our existing technical knowledge and practical experience, and just for reference only. The good application of the product not only depends on the quality of the product, but also on many factors beyond our capabilities. Therefore, SIWAY cannot guarantee that this product is suitable for various usage conditions, and any written complaints about product quality must be issued within six months of the product being shipped. Complaints that are not written or later than the time limit for complaints will not be accepted. Before using this product, the user should determine the applicability of this product and fully consider all possible risks and responsibilities. The further application and processing of our products are beyond our control. Therefore, our responsibility for the products provided is limited to the parts delivered by us and used by you. It is not responsible for the indirect losses caused by the use of our products. The technical support and customer service center of our marketing department are willing to provide you with product consultation and application technical services. Welcome to contact us.