In the evolving world of construction and manufacturing, sealants play a pivotal role in ensuring durability, weather resistance, and structural integrity. Among the top contenders, polyurethane sealant has emerged as a versatile solution for professionals. This guide explores its applications, pros and cons, comparison with silicone, and best practices for use—helping you make informed decisions for your next project.

What is Polyurethane Sealant Used For?

Polyurethane sealant is a high-performance adhesive widely used in industries requiring robust, flexible seals. Key applications include:

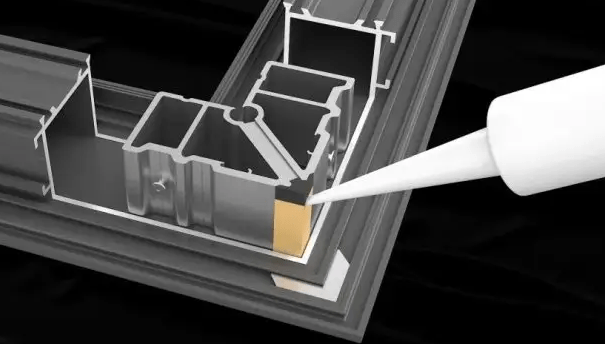

- Construction: Sealing expansion joints, window frames, and roofing systems.

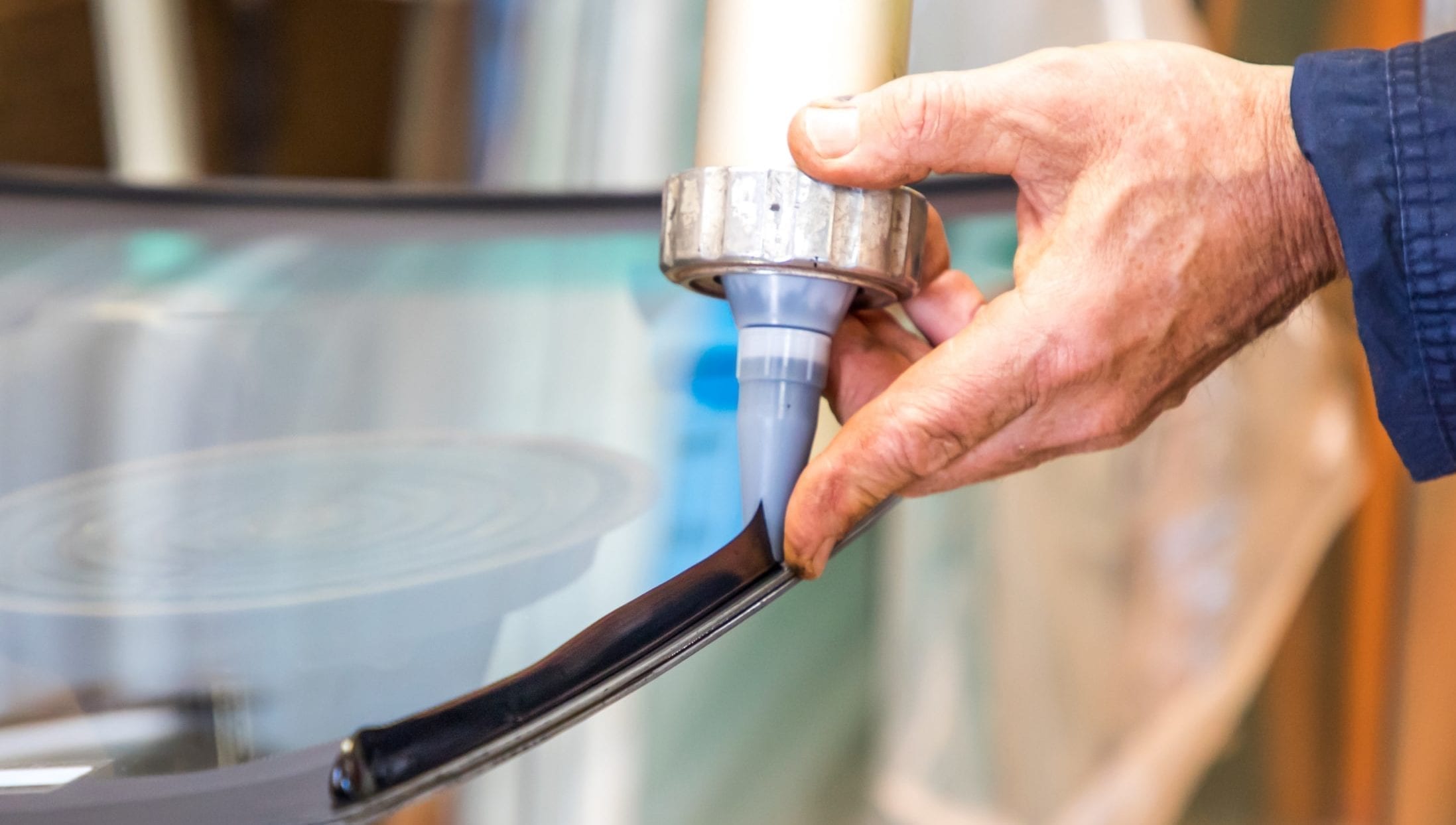

- Automotive: Bonding windshields and dampening vibrations.

- Marine: Waterproofing boat hulls and decks.

- Infrastructure: Repairing cracks in bridges and concrete structures.

Its adaptability to diverse materials—wood, metal, concrete, and plastics—makes it a go-to choice for dynamic environments.

Advantages and Disadvantages of Polyurethane Sealant

Pros:

- Durability: Resists abrasion, chemicals, and extreme temperatures (-40°F to 200°F).

- Flexibility: Accommodates substrate movement without cracking.

- Adhesion: Bonds strongly to most surfaces, even without primers.

- Paintable: Unlike silicone, it accepts coatings for seamless finishes.

Cons:

- Curing Time: Takes 24–48 hours to fully cure, slower than some alternatives.

- UV Sensitivity: Requires topcoats for prolonged outdoor use.

- Cleanup: Solvents like acetone are needed before curing.

Silicone vs. Polyurethane: Which is Better?

The choice depends on the project’s demands:

- Polyurethane excels in high-movement joints (e.g., expansion joints), painted surfaces, and areas needing structural strength.

- Silicone is superior for UV-heavy environments (e.g., exterior glass) and moisture-prone zones (bathrooms, kitchens) due to mold resistance.

For projects requiring both flexibility and paintability, polyurethane is often the optimal pick.

When to Use Polyurethane Sealant

Opt for polyurethane when:

- Substrates experience frequent movement or vibration.

- A painted finish is required.

- Long-term durability in harsh conditions is critical.

Avoid using it in direct, unpainted sunlight or areas requiring immediate water exposure (cure time matters).

How to Apply Polyurethane Sealant

- Prep: Clean and dry surfaces; remove old sealant. Use masking tape for clean edges.

- Cut & Load: Cut nozzle diagonally to desired bead size; load into caulking gun.

- Apply: Steadily dispense sealant into joints.

- Smooth: Use a tool or wet finger to tool the bead.

- Cure: Allow 24–48 hours before painting or stressing the seal.

Conclusion: Elevate Your Projects with Polyurethane Sealant

Polyurethane sealant’s blend of strength, flexibility, and adaptability makes it indispensable for modern construction and repair challenges. While silicone remains ideal for specific scenarios, polyurethane’s paintable finish and superior adhesion cater to dynamic, high-performance applications.

For professionals seeking reliable solutions, shanghai siway offers premium polyurethane sealants engineered for excellence. Explore our range to ensure your projects stand the test of time—combining innovation with unmatched durability.

Post time: May-09-2025