When the temperature is high and the rain continues, it will not only have a certain impact on the production of our factory, but many customers are also very concerned about the storage of sealants.

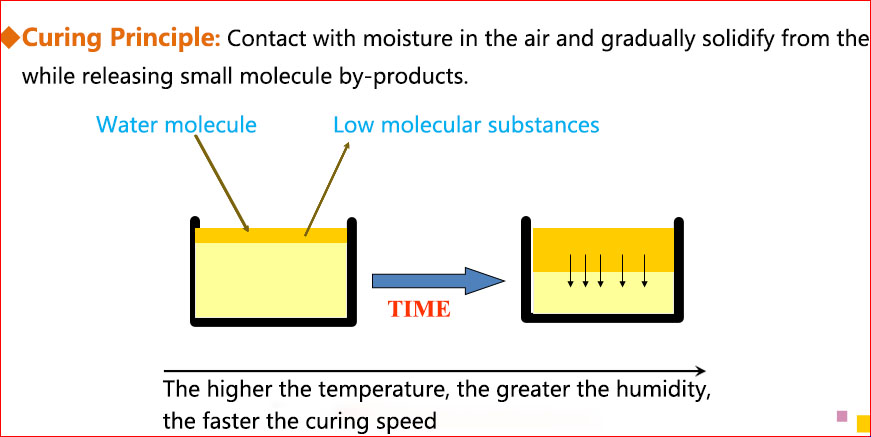

Silicone sealant is room temperature vulcanized silicone rubber. It is a paste made of 107 silicone rubber and filler as the main raw material, supplemented by crosslinking agent, thixotropic agent, coupling agent, and catalyst in a vacuum state. It reacts with water in the air and solidifies to form elastic silicone rubber.

Silicone sealant products have strict requirements on the storage environment. Poor storage environment will reduce the performance of the silicone sealant, or even make it harden. In severe cases, the performance of a certain aspect of the silicone sealants will be lost, and the product will be scrapped.

Let's talk about some silicone sealants storage tips.

In a high temperature environment, silicone sealant will accelerate aging, produce a "reduction" phenomenon, accelerate the loss of some properties, and shorten the shelf life. Therefore, the storage temperature has a great influence on the quality of silicone sealant, and the storage temperature is required not to exceed 27°C (80.6°F).

In a low-temperature environment, too low ambient temperature will cause the cross-linking agent and coupling agent in the silicone glue to crystallize. The crystals will cause poor appearance of the glue and uneven local additives. When sizing, the colloid can be cured locally but not cured locally. Therefore, crystallized silicone sealant cannot be used. In order to prevent silicone rubber from crystallizing, the storage environment should not be lower than -5°C(23℉).

In a high-humidity environment, silicone sealant solidifies when it encounters water vapor. The greater the relative humidity is in the storage environment, the faster the silicone sealant cures.Many silicone sealants produce a large amount of dry sealant 3-5 months after production, which is directly related to the relative humidity of the storage environment is too high, and it is more appropriate to require the relative humidity of the storage environment to be ≤70%.

All in all, silicone rubber products should be stored in a dry, ventilated, and cool place. The best storage temperature is between -5 and 27°C(23--80.6℉), and the best storage humidity is ≤70%. It avoids storing in places exposed to wind, rain, and direct sunlight. Under normal transportation and storage conditions, the storage period is at least 6 months from the date of production.

In order to prevent the deterioration of the quality of silicone rubber products during the storage period, the warehouse should be located in a cool place without direct sunlight. It is also not possible to choose low-lying places that are prone to water accumulation. For warehouses with high temperature, we need to do a good job of cooling the roof. The warehouse with a heat insulation layer on the roof is the best, and should be ventilated at the same time. If conditions permit, the warehouse is equipped with air conditioners and dehumidifiers to keep the warehouse at a constant temperature and humidity during the summer and rainy seasons.

Post time: Aug-23-2023