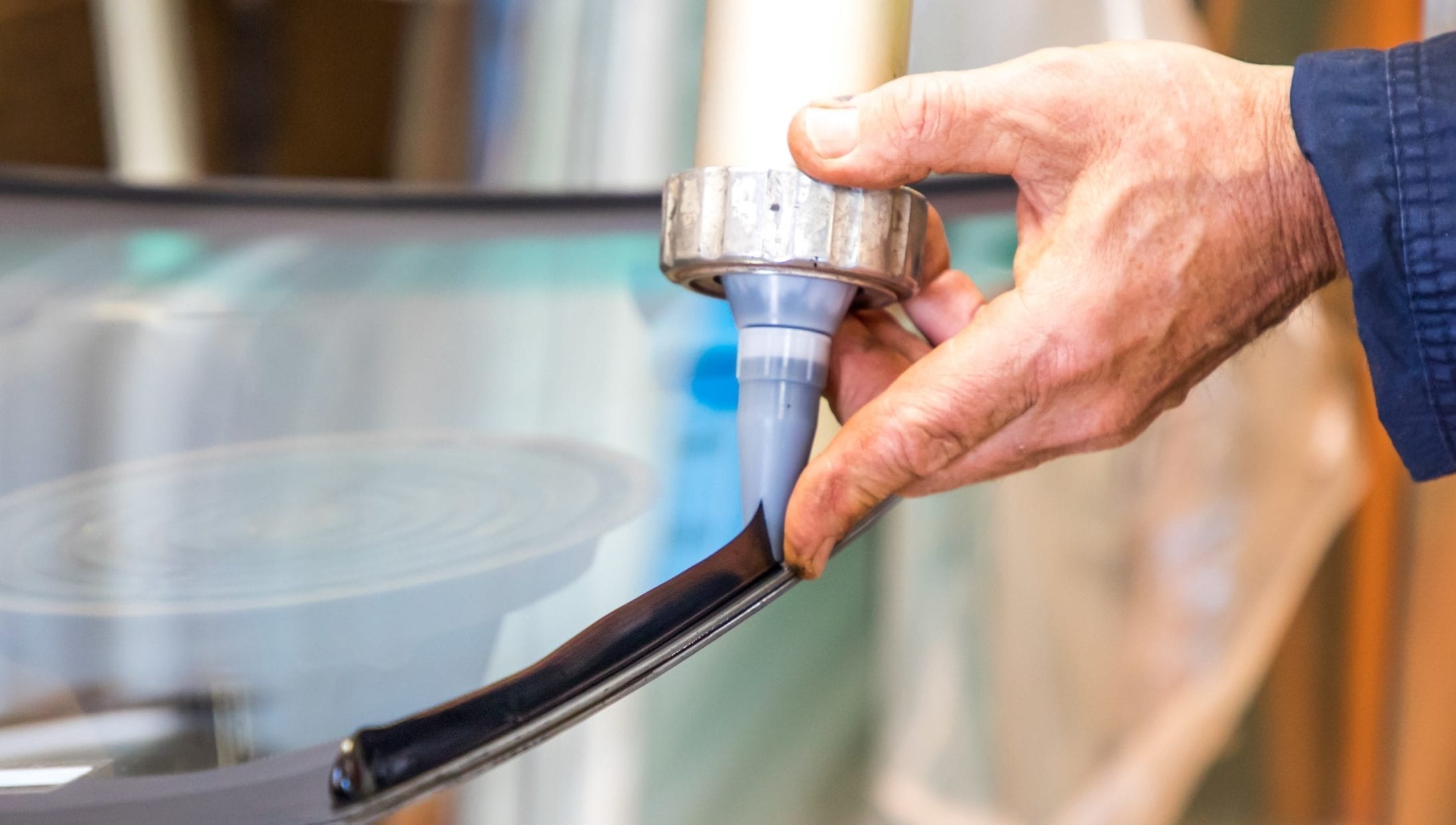

SV-312 One- component Polyurethane Windshield Glass Sealant Adhesive

Product Description

MOQ:10 Drums

PACKAGING

● 310ml/ tube, aluminum tube

● 400ml/ tube, soft bag

● 600ml/ tube, soft bag

● 240kg/ drum, iron drum

● Other specifications

COLOURS

SV628 is available in black, gray, white and other customized colours.

FEATURES

● Easy to cut and facilitate secondary maintenance.

● No need for black primer construction.

● Good extrusion and thixotropy, no sagging.

● Environmentally friendly and solvent-free.

Typical Properties

These values are not intended for use in preparing specifications

| Project | Guideline | Technique Data | Typical value |

| Exterior | / | homogeneous paste | homogeneous paste |

| density g/cm 3 | GB/T 13447.2 | 1.47 | |

| extrudability g/min | GB/T 13477.4 | ≥90 | 130 |

| Droop mm | GB/T 13477.6 | 0 | |

| Surface drying time ② min | GB/T 13477.5 | 20~45 | 30 |

| Curing speed mm/d | HG/T 4363 | 3.1 | |

| Non-volatile content% | GB/T 2793 | ≥98 | 99 |

| hardness Shao A | GB/T 531.1 | 55 | |

| Tensile strengthMPa | GB/T 528 | ≥3.0 | 3.5 |

| Elongation at break % | GB/T 528 | 330 | |

| Tear strength N/mm | GB/T 529 | ≥7.0 | 10.0 |

| Tensile shear strengthMPa | GB/T 7124 | 2.0 | |

| Working temperature/℃ | / | -40~90 |

①In 23 ± 2 ℃、 50 ± 5%RH Test data below; ② The test values of different tack drying times will be different depending on the ambient temperature and humidity.

The main purpose:

Bonding and sealing repair of automobile windshield and side window glass, installation and sealing of low-speed electric vehicle glass .

Product Information

Instructions for use

● In order to ensure the bonding effect and the compatibility between the product and the base material, tests should be conducted on the actual base material and environment in advance.

● Not suitable for use on frozen or wet surfaces, substrates containing silicone oil, or silicone rubber.

● The surface of the adhered substrate must be clean and dry, free of dust, oil and water stains. The adhered substrate should be cleaned and pre-treated with Pusada cleaning agent or primer. Failure to do so may cause adhesion. Connection failure.

● Ambient temperature and humidity have a great influence on the surface drying and curing of sealant. Recommended construction environment temperature 5 ~35℃, humidity 50~70%RH. temperature below At 5℃, it is recommended to put the product in the placed Heating in an environment of 30-40℃ 1h reuse (heating time cannot exceed 3h).

● The sealed node part can be modified and smoothed with a scraper or hard foam strip. Some detailed modifications can be smoothed with soapy water.

● A compatibility test needs to be done before spraying. Painting can only be done after the surface is dry . Do not expose to baking temperatures until fully cured, otherwise bubbling will occur. Pay attention to the thickness and hardness of the coating, Paint brittleness can reduce the elasticity of the glue and cause the paint layer to crack.

● Incompletely cured silicone glue and silane-terminated modified glue, alcohol and alcohol-containing solvents will hinder the SIWAY18A-3 For normal curing, direct contact between the two should be prevented.

● For construction methods, please refer to the construction instructions or consult our technical personnel.

Clean up

● Uncured SIWAY313-A It can be removed from tools or equipment with cleaning agents or appropriate solvents. After curing, it can only be removed mechanically and the surface cleaned.

Transportation and storage

● Transportation: Moisture-proof, rain-proof, sun-proof, high temperature proof, Keep away from heat sources, handle with care, and avoid crushing or collision.

● Storage: Seal and store in a low temperature, dry place, recommended storage temperature 5 ~ 25℃, humidity ≤50%RH.

● Storage period: 9 months

Safety Information

● Store away from children.

● Avoid contact with eyes and skin. Accidental contact with skin, Wipe it with a cloth first, Then wash with soap; Accidental contact with eyes, Seek medical attention as soon as possible after flushing with plenty of water.

Contact Us

Shanghai Siway Curtain Material Co.Ltd

No.1 Puhui Road ,Songjiang Dist,Shanghai,CHINA Tel: +86 21 37682288

Fax:+86 21 37682288