At present, there are many common types of single-component reactive elastic sealants on the market, mainly silicone and polyurethane sealant products. Different types of elastic sealants have differences in their active functional groups and cured main chain structures. As a result, there are more or less limitations in its applicable parts and fields. Here, we introduce the curing mechanisms of several common one-component reactive elastic sealants and compare the advantages and disadvantages of different types of elastic sealants, so as to deepen our understanding and make appropriate choices in practical applications.

1. Common one-component reactive elastic sealant curing mechanism

Common one-component reactive elastic sealants mainly include: silicone (SR), polyurethane (PU), silyl-terminated modified polyurethane (SPU), silyl-terminated polyether (MS),The prepolymer has different active functional groups and different curing reaction mechanisms.

1.1 Curing mechanism of silicone elastomer sealant

Figure 1. Curing mechanism of silicone sealant

When silicone sealants are used, the prepolymer reacts with trace amounts of moisture in the air and then solidifies or vulcanizes under the action of a catalyst. The by-products are small molecular substances. The mechanism is shown in Figure 1. According to the different small molecular substances released during curing, silicone sealant can also be divided into deacidification type, deketoxime type, and dealcoholization type. The advantages and disadvantages of these types of silicone glue are summarized in Table 1.

Table 1.Comparison of the advantages and disadvantages of several types of silicone adhesives

1.2 Curing mechanism of polyurethane elastic sealant

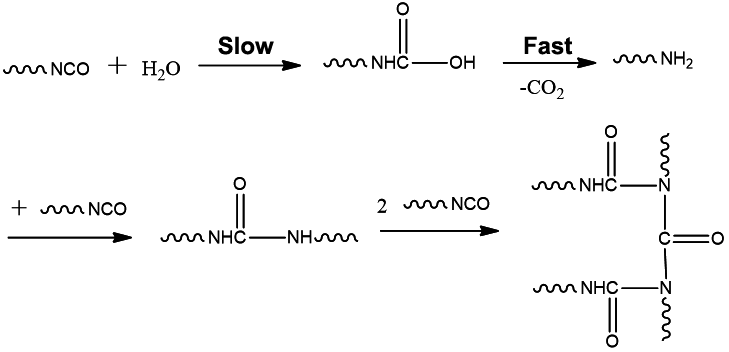

One-component polyurethane sealant (PU) is a type of polymer containing repeating urethane segments (-NHCOO-) in the main chain of the molecule. The curing mechanism is that isocyanate reacts with water to form an unstable intermediate carbamate, which then rapidly decomposes to generate CO2 and amine, and then the amine reacts with excess isocyanate in the system, and finally forms an elastomer with a network structure. Its curing reaction formula is as follows:

Figure 1.Curing reaction mechanism of polyurethane sealant

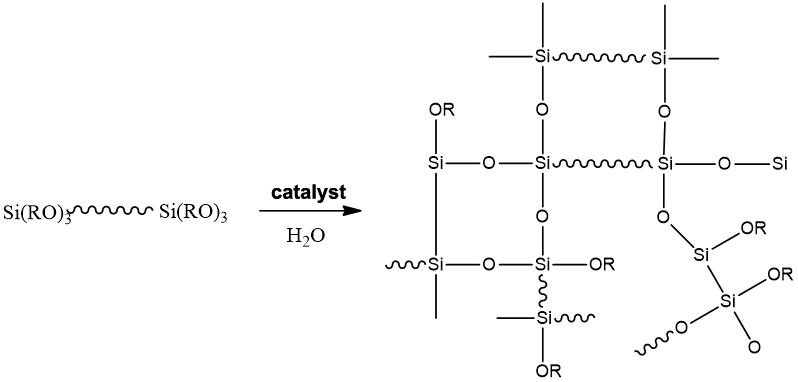

In view of some shortcomings of polyurethane sealants, polyurethane has recently been modified by silane to prepare adhesives, forming a new type of sealing adhesive with a main chain of polyurethane structure and an alkoxysilane end group, called silane-modified polyurethane sealant (SPU). The curing reaction of this type of sealant is similar to that of silicone, that is, the alkoxy groups react with moisture to undergo hydrolysis and polycondensation to form a stable Si-O-Si three-dimensional network structure (Figure 3). The network cross-linking points and between the cross-linking points are polyurethane flexible segment structures.

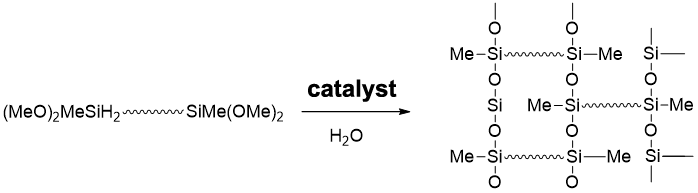

1.4 Curing mechanism of silyl-terminated polyether sealants

silyl-terminated polyether sealant (MS) is a single component elastic adhesive based on silane modification. It combines the advantages of both polyurethane and silicone, is a new generation of adhesive sealant products, free of PVC, silicone oil, isocyanate and solvent. MS adhesive reacts with the moisture in the air at room temperature, so that the silanized polymer with -Si(OR) OR -SIR (OR)- structure is hydrolyzed at the chain end and cross-linked into an elastomer with Si-O-Si network structure to achieve sealing and bonding effect. The curing reaction process is as follows:

Figure 4. Cure mechanism of silyl-terminated polyether sealant

2. Comparison of the advantages and disadvantages of common single-component reactive elastic sealants

2.1 Advantages and disadvantages of silicone sealants

⑴Advantages of silicone sealant:

① Excellent weather resistance, oxygen resistance, ozone resistance and ultraviolet resistance; ② Good low temperature flexibility.

⑵Disadvantages of silicone sealant:

①Poor re-decoration and cannot be painted; ②Low tear strength; ③Insufficient oil resistance; ④Not puncture-resistant; ⑤The adhesive layer easily produces oily leachate that contaminates concrete, stone and other loose substrates.

2.2 Advantages and Disadvantages of Polyurethane Sealants

⑴Advantages of polyurethane sealant:

① Good adhesion to a variety of substrates; ② Excellent low-temperature flexibility; ③ Good elasticity and excellent recovery properties, suitable for dynamic joints; ④ High mechanical strength, excellent wear resistance, oil resistance and Biological aging resistance; ⑤ Most one-component moisture-curing polyurethane sealants are solvent-free and have no pollution to the substrate and the environment; ⑥ The surface of the sealant can be painted and easy to use.

⑵Disadvantages of polyurethane sealant:

① When curing in a high-temperature and high-humidity environment at a relatively fast speed, bubbles are easily generated, which affects the performance of the sealant; ② When bonding and sealing components of non-porous substrates (such as glass, metal, etc.), a primer is generally required; ③ Shallow The color formula is susceptible to UV aging, and the storage stability of the glue is greatly affected by packaging and external conditions; ④ The heat resistance and aging resistance are slightly insufficient.

2.3 Advantages and disadvantages of silane-modified polyurethane sealants

⑴Advantages of silane modified polyurethane sealant:

① Curing does not produce bubbles; ② Has good flexibility, hydrolysis resistance and chemical resistance stability; ③ Excellent weather resistance, heat resistance, aging resistance, product storage stability; ④ Wide adaptability to substrates, when bonding Generally, no primer is required; ⑤The surface can be painted.

⑵Disadvantages of silane modified polyurethane sealant:

① The UV resistance is not as good as that of silicone sealant; ② The tear resistance is slightly worse than that of polyurethane sealant.

2.4 Advantages and disadvantages of silyl-terminated polyether sealants

⑴Advantages of silyl-terminated polyether sealant:

① It has excellent bonding properties to most substrates and can achieve primer-free activation bonding; ② It has better heat resistance and UV aging resistance than ordinary polyurethane; ③ It can be painted on its surface.

⑵Disadvantages of silyl-terminated polyether sealant:

① The weather resistance is not as good as that of silicone silicone, and cracks appear on the surface after aging; ② The adhesion to glass is poor.

Through the above introduction, we have a preliminary understanding of the curing mechanisms of several commonly used types of single-component reactive elastic sealants, and by comparing their advantages and disadvantages, we can achieve an overall understanding of each product. In practical applications, the sealant can be selected according to the actual application conditions of the bonding part to achieve good sealing or bonding of the application part.

Post time: Nov-15-2023